Why Logo Finishes Matter for Paper Packaging

Logo finishes on paper packaging play a crucial role in brand recognition and customer perception. A well-executed finish not only highlights the logo but also communicates quality, attention to detail, and a sense of luxury. Whether it is foil stamping, embossing, or spot UV, these techniques help products stand out on crowded shelves and create a lasting impression. Beyond aesthetics, finishes also enhance the tactile experience, making the packaging more engaging and memorable for consumers.

Popular Logo Finishes on Paper Packaging

🔹 01. Offset Printing – Clear and Consistent Branding

- Best for: Colorful, cost-effective logos on large runs.

Offset printing (CMYK or PMS color) is the most common method for applying a logo directly onto the packaging paper. It ensures accurate color reproduction and is ideal for flat designs with fine details.

✅ Tip: Use PMS (Pantone Matching System) for strict brand color consistency.

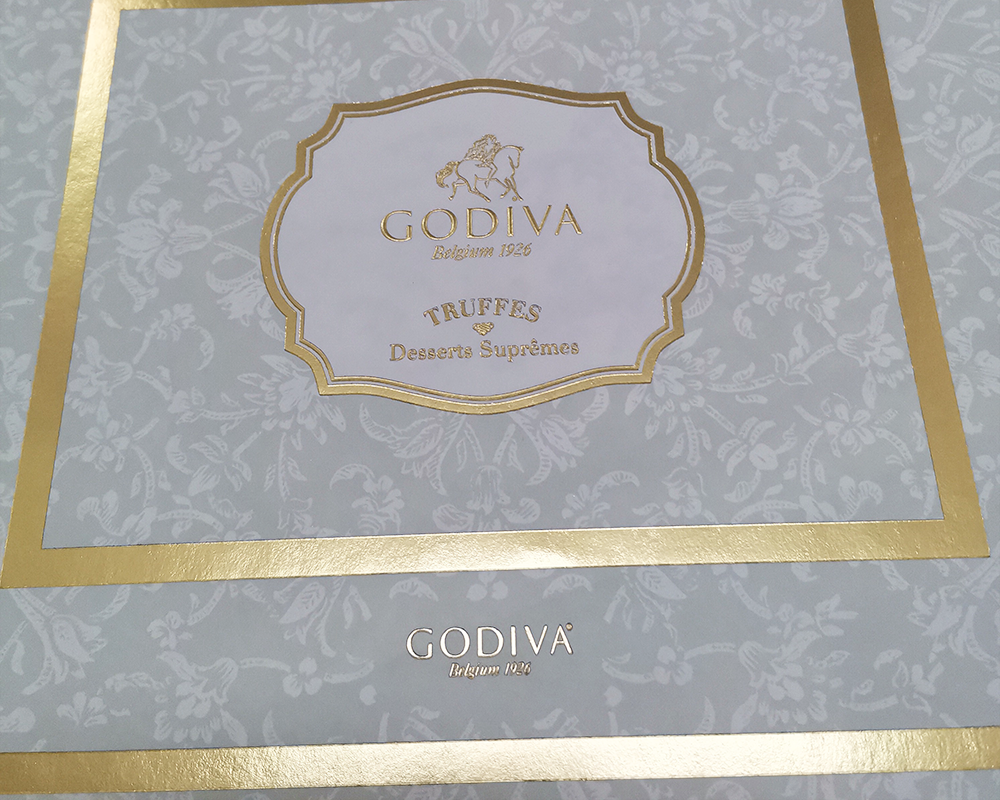

🔹 02. Hot Foil Stamping – Shiny and Luxurious

- Best for: Luxury packaging, premium branding.

Hot foil stamping uses heat and pressure to transfer metallic foil onto the packaging surface through a custom metal die. It’s available in gold, silver, rose gold, holographic, or even custom colors.

Key Benefits:

Creates a shiny, reflective effect

Adds a sense of luxury and sophistication

Excellent for minimal designs with high contrast

🔄 Combine with embossing for a more tactile logo finish.

🔹 03. Embossed Logo – Raised Texture for Premium Feel

- Best for: Tactile, premium unboxing experience.

- Embossing raises the logo above the paper surface by pressing from behind using a metal mold. It gives your logo a 3D effect and a luxurious texture.

- Use Cases:

- Perfume boxes

- Premium cosmetics

- Corporate gift boxes

🔹 04. Debossed Logo – Subtle and Refined

- Best for: Understated elegance.

Debossing presses the logo into the paper, creating a sunken effect. It offers a refined and minimalist look, and can be used with or without ink or foil.

💡 Often used for eco-friendly kraft boxes or matte black rigid boxes.

🔹05. Spot UV Logo – Glossy Contrast

- Best for: Modern, high-contrast packaging.

- Spot UV applies a clear, glossy coating only to specific areas like your logo. The process uses ultraviolet light to cure the varnish, giving a sharp gloss finish.

- Common Combinations:

- Matte lamination + Spot UV = Strong contrast

- Spot UV + Embossing = Shine and depth

🔹 06. Silkscreen Printing – Bold and Versatile

Silkscreen printing, also known as screen printing, is a manual or semi-automatic technique where ink is pushed through a mesh screen onto the surface of the packaging.

Unlike offset printing, it’s usually used for solid color logos, especially when high color opacity or printing on non-absorbent surfaces is needed.

✅ Advantages:

- Strong ink coverage and color saturation

- Works on coated paper, plastic, textured surfaces, or rigid boxes

- Ideal for bold, single-color logos or metallic inks

📦 Commonly used in small-batch premium packaging, wooden boxes, Plastic surface gift sets, Textiles and Leather

✅ Tip:Silkscreen printing is also used for applying glitter powder, UV varnish, and even raised ink effects. It’s one of the most versatile logo finishing methods when precision and ink layering are required.

🔹 07. Glitter Powder – Glamorous & Eye-Catching

Best for: Cosmetic & festive packaging.

This process involves screen printing glitter powders (gold, silver, or colored) onto the logo area. It’s perfect for products like nail polish, holiday gift sets, and glam cosmetic boxes.

✅ Cost Considerations for Different Logo Finishes

The cost of logo finishes on paper packaging depends mainly on the size of the logo area and the type of finishing technique applied. Standard hot stamping is often one of the most economical options, but when combined with embossing or debossing to create a raised or tactile effect, the cost increases due to additional tooling and processing steps. Larger logos naturally consume more foil or coating materials, which also adds to the expense.

Among all options, foil stamping with embossing tends to be more costly because it requires both heat-transfer foils and custom molds. In contrast, techniques like spot UV or silk screen printing can be more budget-friendly for smaller areas. When selecting a finish, brands should balance visual impact, durability, and cost to ensure the packaging both looks premium and stays within budget.

🧭 Choosing the Right Logo Finish for Your Brand

| Logo Effect | Recommended Technique |

|---|---|

| Luxurious & eye-catching | Hot foil stamping |

| Tactile feel | Embossing or Debossing |

| High color accuracy | Offset printing |

| Glossy highlight | Spot UV |

| Festive & sparkling | Glittering powder |

🎯 Custom Logo Packaging with Longgreen

We help brands bring their packaging vision to life — from concept to delivery. Whether you need luxury gift boxes, eco-friendly kraft packaging, or creative finishes for retail displays, we’ve got you covered.

📩 Let’s talk about your project now!