What is the difference between Coating and Lamination

In paper packaging, surface finishing is more than decoration—it directly affects brand perception, durability, and customer experience. Among the most common finishing methods, coating and lamination are often compared, yet they serve different purposes. Understanding their differences helps brands choose the right finishing technique for both performance and presentation.

Why Coating and Lamination Matter

- Brand Appeal – Finishes enhance colors, texture, and visual impact.

- Customer Experience – Gloss, matte, or soft-touch surfaces influence how packaging feels in hand.

- Durability & Protection – Both methods protect against scratches, stains, and moisture, but to different degrees.

- Sustainability & Cost – The choice affects recyclability and overall budget.

What is Coating in Paper Packaging?

Coating involves applying a thin liquid layer (varnish or UV-based) directly onto printed paper. It dries quickly, adds visual effect, and provides a moderate level of protection.

Popular Coating Types

- Gloss Varnish Coating

- Effect: Bright, shiny surface that makes colors pop.

- Best for: Retail packaging with strong shelf impact (cosmetics, food, promotions).

- Matte Varnish Coating

- Effect: Smooth, non-reflective look for understated elegance.

- Best for: Luxury brands and minimalist packaging.

- Reverse UV Coating

- Effect: Combines gloss and matte in one design for strong contrast.

- Best for: Innovative packaging requiring visual highlights.

- Soft Touch Varnish Coating

- Effect: Velvet-like texture that feels premium.

- Best for: Perfume, jewelry, and other high-end products.

What is Lamination in Paper Packaging?

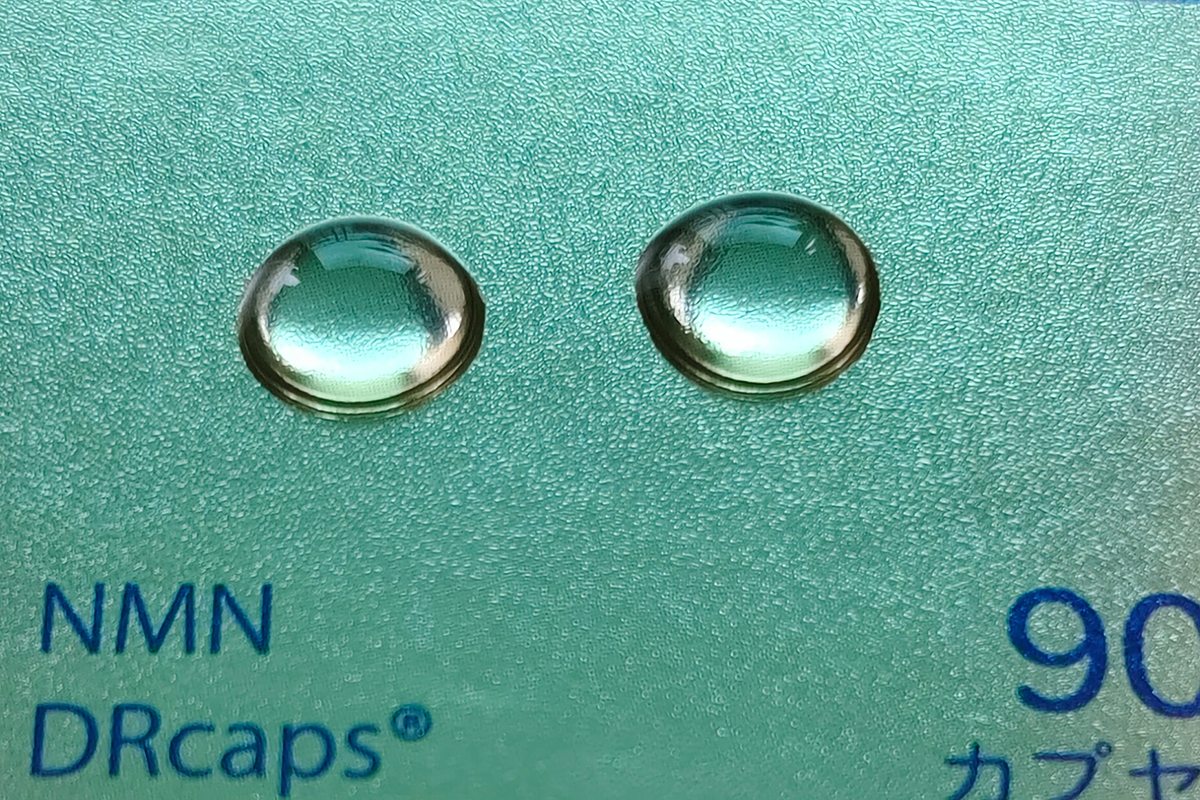

Lamination adds a thin plastic film layer (usually PP) over printed paper. This film increases durability, improves moisture resistance, and creates a more tactile surface.

Popular Lamination Types

- Gloss PP Lamination

- Effect: High-gloss finish that intensifies printed colors.

- Best for: Promotional packaging, retail boxes requiring strong visuals.

- Matte PP Lamination

- Effect: Soft, refined surface with reduced glare.

- Best for: Premium brands seeking an elegant look.

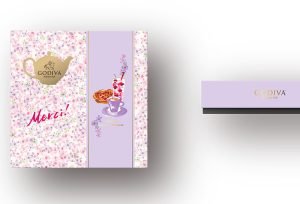

- Soft Touch PP Lamination

- Effect: Luxurious, silky texture that elevates brand value.

- Best for: Perfume, wine, cosmetics, and jewelry packaging.

Coating vs Lamination: Key Differences

| Aspect | Coating (Varnish / UV) | Lamination (PP Film) |

|---|---|---|

| Process | Liquid applied directly on paper | Thin plastic film bonded to paper |

| Durability | Moderate protection | Strong protection against moisture & scratches |

| Appearance | Glossy, matte, textured effects | Gloss, matte, or velvet-like finish |

| Cost | Lower cost, budget-friendly | Higher cost due to material & processing |

| Eco-Friendliness | Easier to recycle, less plastic usage | Some films are not recyclable (eco options rising) |

| Best For | Fast-moving consumer goods, creative effects | Luxury, high-value packaging needing durability |

How to Choose the Right Finish

- Budget Considerations: Coating is more economical, while lamination justifies its cost with superior protection.

- Product Type: Luxury packaging benefits from lamination or soft-touch finishes, while everyday products may only need coating.

- Brand Positioning: Gloss for vibrancy, matte for elegance, soft-touch for exclusivity.

- Sustainability: Ask suppliers about recyclable films and water-based coatings.

Final Thoughts

Coating and lamination each play a critical role in shaping packaging performance and brand image. Coating is ideal for cost-effective protection and creative finishes, while lamination offers premium durability and tactile effects. The right choice depends on your budget, product positioning, and sustainability goals.

At Longgreen Packaging, we help global brands find the best finishing solution—whether it’s a simple varnish, a soft-touch coating, or durable PP lamination—tailored to your packaging needs.

FAQ: Coating vs Lamination in Paper Packaging

1. What is the difference between coating and lamination?

Coating applies a liquid finish directly on paper, while lamination adds a plastic film. Lamination offers higher durability but costs more.

2. Which is more durable?

Lamination (both gloss and matte) provides stronger protection against scratches and moisture.

3. Which is more eco-friendly?

Coatings are generally more recyclable. However, newer eco-friendly lamination films are emerging.

4. Can both be combined?

Yes. For example, matte lamination with spot UV coating on a logo creates a striking contrast.

Yes. For example, a matte lamination can be enhanced with spot UV coating on the logo to create a striking contrast.

📩 Let’s talk about your packaging project today!