A concise, professional reference for packaging buyers, sourcing managers, and brand teams.

Choosing the right packaging material determines print quality, structural strength, sustainability, and total cost. This guide highlights the essential paperboards, specialty papers, and inner tray options most commonly used in cosmetics, fragrance, premium gifts, consumer goods, and e-commerce packaging.

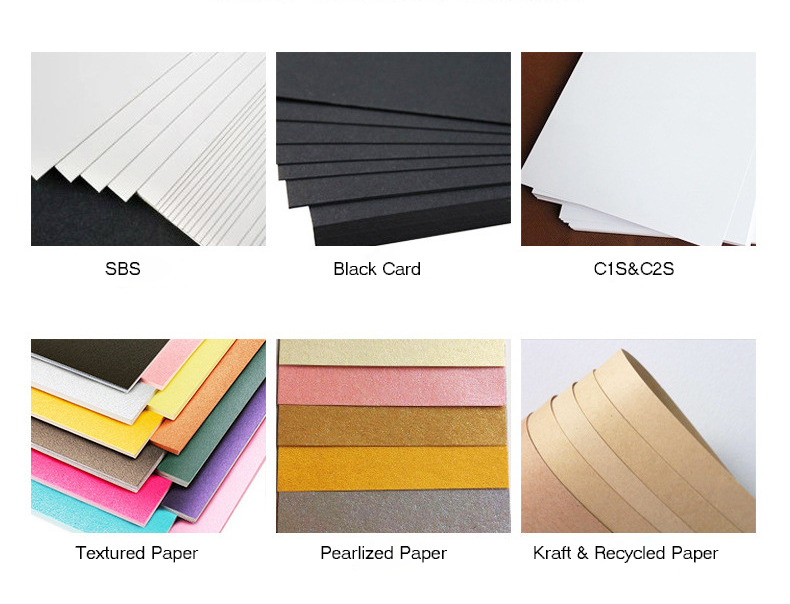

01. Core Paperboard Materials (For Rigid Boxes & Folding Cartons)

C1S / C2S Coated Art Paper

Best for: Folding cartons, rigid box wrapping

- C1S: Smooth print surface outside; economical.

- C2S: Premium print outside & inside; better moisture resistance.

Why buyers choose it: Reliable print performance, stable supply, best value.

SBS (Solid Bleached Sulfate)

Best for: Premium beauty & food packaging

Key benefits:

- Pure white base → excellent color accuracy

- High cleanliness & stiffness

- Strong premium perception

Note: Virgin fiber; recyclable but less eco-friendly than recycled grades.

Recycled Paperboard & Grayboard

Best for: Sustainable packaging, rigid box cores

- 100% recycled options available

- Grayboard delivers strong structure at a competitive cost

Why buyers choose it: Low carbon footprint + ideal for eco branding.

Textured Paper

Best for: High-end rigid boxes

Includes linen, leather grain, wood grain, felt-mark textures.

Benefits:

- Strong tactile experience

- Hides fingerprints

- Luxury look without expensive finishes

02. Specialty Papers (High-Impact Visual & Tactile Effects)

A practical shortlist used in real production.

Most Requested by Premium Brands

- Textured paper(rigid boxes / gift sets)

- Pearlized & metallic paper(perfume & festive packaging)

- Soft-touch paper(beauty, fragrance)

- Black dyed-through paper(clean edges, luxury cards)

- Kraft & recycled kraft(eco branding)

- C1S / C2S art paper(industry standard for printing)

Extended Options

- Cotton paper(brand cards / certificates)

- Glitter paper(seasonal packaging)

- Synthetic paper(waterproof tags)

- Stone paper(tear-resistant, eco alternative)

- Specialty label paper(wine, fragrance, glass bottles)

👉 Tip for buyers: Specialty papers often require adhesion tests for foil stamping, screen printing, or lamination.

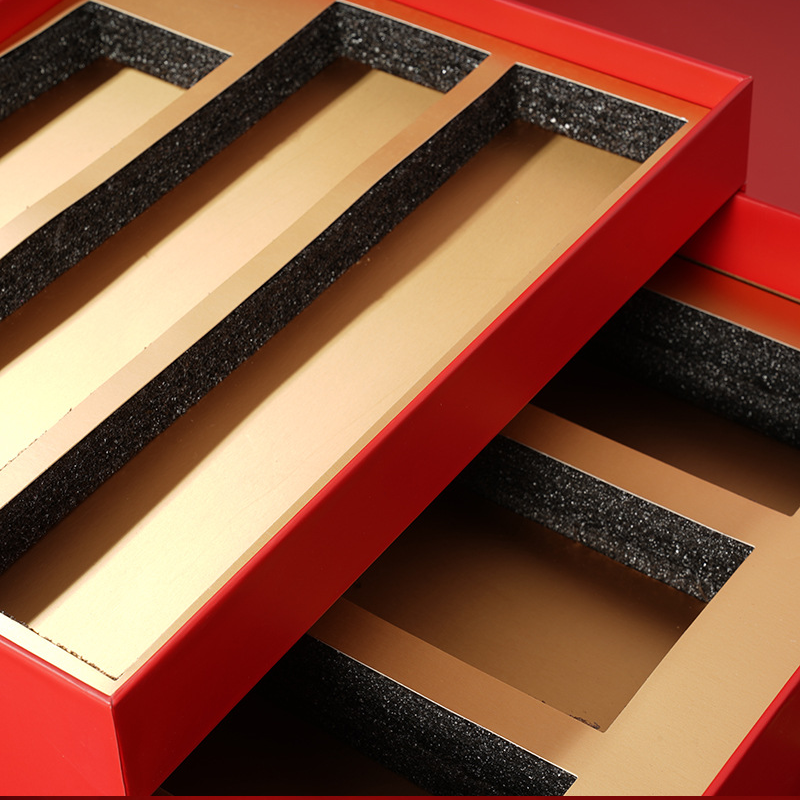

03. Inner Tray (Inset) Materials

Selected based on product fragility, presentation level, sustainability goals, and cost.

Paperboard / Molded Pulp Inserts

- Recyclable, lightweight, customizable

- Suitable for beauty sets, gift boxes

- Best for brands with strong sustainability targets

PET Inserts ( PET flocking)

- Transparent, rigid, high visibility

- Common in cosmetics & electronics

- Recyclable (varies by region)

EVA Foam

- Clean finish, strong cushioning

- Ideal for perfumes, glass, electronics

- Available in custom colors and densities

Sponge & EPE tray

- Cost-effective protection

- Used for glassware, gifts, and industrial items

- EPE = better shock absorption than sponge

04. How Procurement Teams Choose Materials (Decision Framework)

1) Brand Positioning

- Luxury → textured, pearlized, soft-touch, SBS

- Eco-focused → kraft, recycled paperboard, molded pulp

- Mass retail → C2S, grayboard, PET inserts

2) Printing & Finishing Requirements

- Fine graphics → C2S, SBS

- Hot foil + embossing → textured, soft-touch

- Dark colors without white edges → dyed-through papers

3) Protection Level

- Fragile items → EVA / EPE

- Lightweight products → paperboard trays

4) Budget & Lead Time

- C1S/C2S → best price-performance

- Specialty papers → higher MOQ & cost

- Foam trays → stable cost, lower tooling cost

05. Quick Material Recommendations (Based on Industry Use Cases)

Cosmetics / Skin Care

- Art paper (C2S) + soft-touch coating

- Textured wrapping paper + EVA inserts

Perfume & Fragrance

- Pearlized / metallic / textured paper

- EVA or thermoformed PET insert

Eco-Friendly Products

- Recycled kraft

- Molded pulp tray

- Uncoated recycled wrapping paper

Premium Gift Sets

- Black dyed-through

- Linen texture

- EVA or paperboard insert

06. Summary for Buyers

A strong packaging solution balances visual impact, sustainability, protection, and cost efficiency.

Focus on three decisions:

- Outer paper → determines appearance & print quality

- Structural board → determines strength

- Inner tray → determines protection & unboxing experience

Selecting the right combination ensures the packaging aligns with market positioning and delivers a consistent brand experience.

Need pricing or look for the right material for your next packaging project?

Upload your dieline or project brief, our team can recommend the most cost-effective and production-ready options based on your brand, printing needs, and budget

- Best-fit materials

- Cost comparison

- Lead time

- Sampling options