Soft Touch Lamination in Luxury Packaging

Introduction

In the world of luxury packaging, surface finishing plays a decisive role in shaping how a brand is perceived. Beyond protecting the printed surface, finishes such as Soft Touch Lamination or Soft Touch Coating elevate the tactile and visual appeal of packaging. A well-chosen finish can make the difference between a package that feels ordinary and one that conveys exclusivity and refinement.

This guide focuses on Soft Touch Lamination—why it has become the preferred choice for premium packaging—and also looks briefly at other common finishing options.

What Is Soft Touch Lamination?

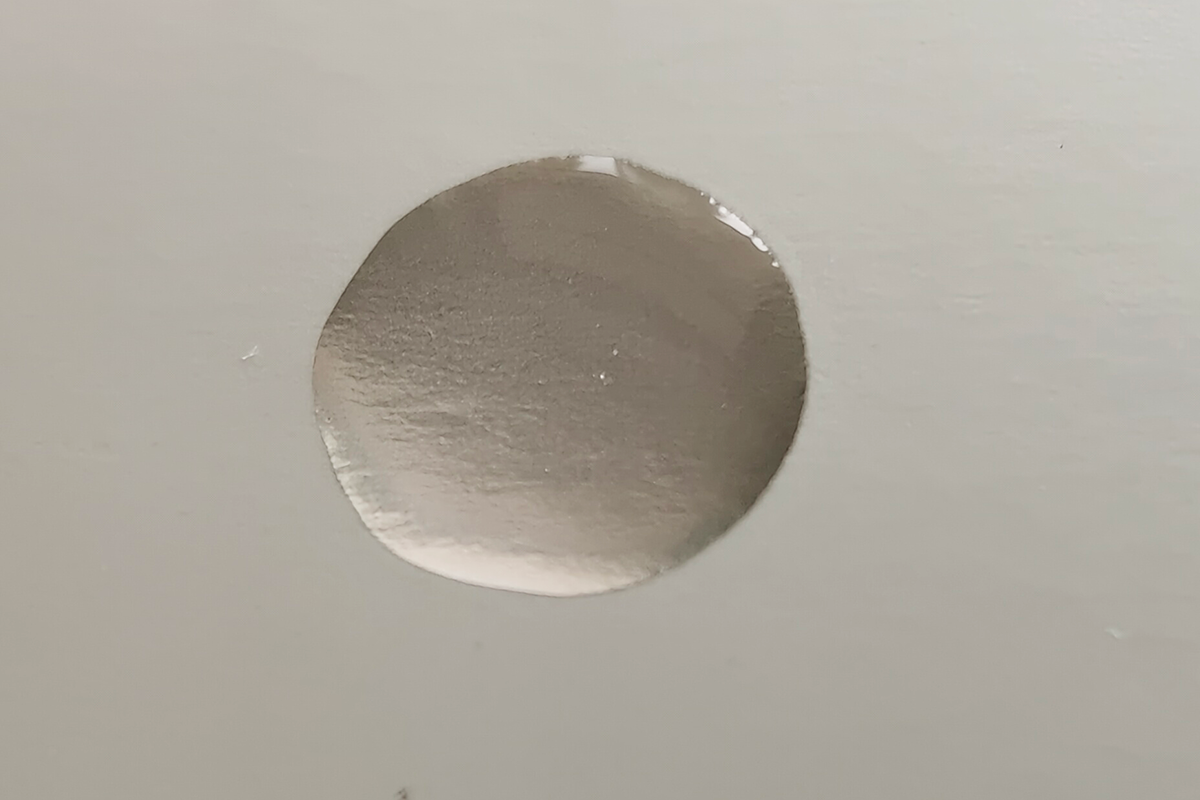

Soft Touch Lamination is a premium finishing technique where a thin, matte film is applied over printed paper or board. Unlike standard glossy or matte laminates, it creates a unique velvety texture that feels warm and luxurious to the touch.

Key characteristics include:

- Velvet-like texture: Adds a sensory dimension, encouraging customers to interact with the packaging.

- Enhanced color depth: The matte film slightly enriches printed colors, giving them a soft but elegant appearance.

- Durability: Protects the print from scratches, smudges, and handling wear.

Because of these qualities, Soft Touch Lamination is now widely used in luxury packaging for perfumes, cosmetics, jewelry, and high-end retail products.

Soft Touch Lamination vs. Soft Touch Coating

While the terms are sometimes used interchangeably, there are technical differences:

- Soft Touch Lamination: A plastic film (usually BOPP) applied over the printed surface. It offers stronger durability, consistent texture, and superior protection.

- Soft Touch Coating: A liquid-based varnish applied during printing. It provides a similar tactile feel but is less resistant to scratches compared with lamination.

Which to choose?

- For luxury rigid boxes or premium gift packaging, Soft Touch Lamination is often preferred due to its protective layer and richer effect.

- For cost-sensitive projects or flexible printing runs, Soft Touch Coating may be considered.

Soft Touch Lamination vs. Matte Lamination

Both Soft Touch Lamination and Matte Lamination provide a non-glossy finish, but the customer experience is very different:

- Effect on Appearance

- Matte Lamination: Creates a flat, subdued look that reduces glare and gives packaging a clean, elegant appearance.

- Soft Touch Lamination: Goes beyond the visual effect, adding a velvety, almost suede-like texture that invites customers to touch and hold the packaging.

- Durability

- Matte Lamination: Protects against scratches to some extent, but is prone to showing scuffs and fingerprints.

- Soft Touch Lamination: Offers stronger resistance to scuffs and marks, making it more suitable for luxury items that must remain flawless.

- Cost Comparison

- Matte Lamination: Generally the more economical option, suitable for mid-range retail packaging where elegance is important but budgets are tight.

- Soft Touch Lamination: Costs slightly more due to the specialized film, but the added sensory experience and premium perception often justify the investment for high-end products.

Simply Comparison table of Soft Touch Coating, Soft Touch Lamination, and Matte Lamination

| Feature | Soft Touch Coating | Soft Touch Lamination | Matte Lamination |

|---|---|---|---|

| Application Method | Liquid varnish applied during printing | BOPP film applied over the print | Matte film applied over the print |

| Texture & Feel | Silky, soft effect, but less consistent | Velvety, suede-like, premium touch | Smooth, flat, elegant but no tactile luxury |

| Durability | Moderate scratch resistance; can wear off | High durability, strong resistance to scuffs, fingerprints, and moisture | Good protection, but prone to visible scuffs and fingerprints |

| Visual Effect | Slightly softens colors; subtle matte look | Enriches colors with soft depth and luxurious appearance | Reduces glare, clean and understated appearance |

| Cost Level | Lower (budget-friendly for short runs) | Higher (premium choice, justified for luxury packaging) | Moderate (economical option for mid-range packaging) |

| Best Suited For | Short-term promotional items, flexible prints | Luxury packaging (perfume, cosmetics, jewelry, premium rigid boxes) | Retail packaging needing elegance without high cost |

Conclusion of Comparison:

If the goal is simply to achieve a subtle, elegant look, Matte Lamination is sufficient. However, if a brand wants to create a strong emotional connection through touch and convey luxury positioning, Soft Touch Lamination provides greater value.

Why Luxury Brands Prefer Soft Touch Lamination

Luxury packaging isn’t just about protecting a product—it’s about creating an emotional connection. Soft Touch Lamination has become a favorite in the luxury segment because it delivers:

- Premium Brand Experience

Customers associate the velvety feel with exclusivity and high quality. This aligns perfectly with the image luxury brands want to project. - Added Shelf Impact

On retail shelves, Soft Touch Lamination helps packaging stand out against glossy finishes. It attracts attention through subtlety rather than shine. - Protection with Elegance

Beyond aesthetics, it resists fingerprints, scratches, and scuffs—essential for high-value products that must arrive in pristine condition.

Other Popular Packaging Finishes (Brief Overview)

While Soft Touch Lamination is a premium option, brands often combine it with other finishing techniques for added impact:

- Gloss Lamination: Vibrant and reflective, ideal for bold retail designs.

- Matte Lamination: Smooth, elegant look with reduced shine.

- Spot UV Coating: Contrasts glossy highlights against matte surfaces.

- Foil Stamping: Adds metallic accents, often used for logos.

- Embossing/Debossing: Creates raised or recessed effects for tactile branding.

When to Choose Soft Touch Lamination

Soft Touch Lamination is particularly effective for:

- Rigid gift boxes for perfumes and cosmetics

- Luxury shopping bags

- Premium product catalogs or brochures

- High-end retail packaging where touch and feel matter

If your brand emphasizes sophistication, Soft Touch Lamination ensures the packaging communicates the same values.

Packaging must do more than protect—it must engage the senses and reinforce brand identity. Soft Touch Lamination delivers a refined tactile experience, excellent durability, and a premium look that resonates with customers.

By comparing Soft Touch Lamination with both Soft Touch Coating and Matte Lamination, it becomes clear that while each has its place, only Soft Touch provides the combination of tactile luxury, durability, and brand-enhancing value.

For businesses seeking to elevate their brand presence, investing in Soft Touch Lamination is not just a finishing choice—it’s a statement of quality.

FAQ: Soft Touch Lamination in Luxury Packaging

Q1. What is the difference between Soft Touch Lamination and Soft Touch Coating?

Soft Touch Lamination uses a thin PP film applied to the packaging surface, while Soft Touch Coating is a liquid-based varnish sprayed or rolled onto the paper. Lamination is generally more durable and resistant to scratches, while coating provides a similar tactile effect at a lower cost.

Q2. Is Soft Touch Lamination eco-friendly?

Yes. Many Soft Touch films are now available in recyclable and biodegradable materials, making them suitable for sustainable packaging projects. If environmental impact is a priority, it’s best to consult your supplier for FSC-certified and eco-friendly options.

Q3. Can Soft Touch Lamination be combined with other finishing techniques?

Absolutely. Popular combinations include Soft Touch + Spot UV for glossy highlights, or Soft Touch + Foil Stamping to enhance logos and text. These contrasts create a premium, multi-sensory effect.

Q4. How durable is Soft Touch Lamination?

It is highly resistant to scratches, moisture, and fingerprints compared to standard matte finishes. This durability makes it ideal for packaging that needs to maintain a flawless appearance through shipping, handling, and display.

Q5. What types of products use Soft Touch Lamination most often?

Soft Touch is commonly used for perfume boxes, cosmetic packaging, jewelry boxes, spirits and wine packaging, and luxury gift boxes. It is also applied to marketing materials like brochures and invitation cards for premium events.

Q6. Does Soft Touch Lamination increase packaging costs significantly?

Yes, it is generally more expensive than standard gloss or matte lamination. However, the perceived value and luxury appeal it adds often outweigh the extra cost, making it a worthwhile investment for premium products.

📩 Let’s talk about your project today and create packaging that truly reflects your brand’s value.